Source: Robotics Industries Association

A once small machine shop transforms into a Tier 1 auto supplier. A bagel basket maker morphs into a precision fabricator for high-tech Fortune 500s. A Canadian shelving manufacturer beats the competition on price. All SMEs with different products serving different industries, but with one thing in common – automation.

Across North America, and the globe, small and medium-sized enterprises (SMEs) outnumber large corporations. Collectively, they employ more people. But they have yet to learn what the big guys already know. SMEs represent the majority of businesses that have yet to realize the advantages of automation and robotics.

The companies that are in the know share the same challenges as other SMEs. Rising raw material and labors costs, stiff prices and offshore competition, quality concerns, skilled worker shortages, worker safety issues, and limited resources that hinder growth and profitability.

The companies that are in the know share the same challenges as other SMEs. Rising raw material and labors costs, stiff prices and offshore competition, quality concerns, skilled worker shortages, worker safety issues, and limited resources that hinder growth and profitability.

The difference? They’re not afraid of change. In fact, they embrace it. They become advocates for it. When we take a closer look, a pattern develops among these companies. They cleverly exploit technology while developing their workforce. They reinvest in their companies’ futures. They get inspired and excited. They become champions for automation. Because they know.

They’re happy to share their experiences with industry and popular media, so everyone can benefit. The result is a strong image among their customers, employees, and other stakeholders. Confidence that breeds more investment, more work, and even more press. A virtual PR de force.

Because these are not fly-by-night companies. These guys come to win. And their growing customer bases know it.

Back Saving, Labor Saving

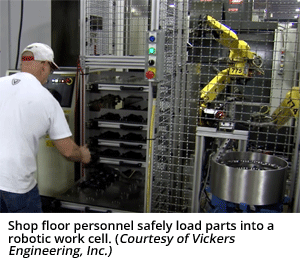

For Vickers Engineering, a medium-sized contract manufacturer in New Troy, Michigan, their foray into robotics was born out of necessity.

“We sort of stumbled upon it,” says Matt Tyler, President and CEO of Vickers, which purchased its first robot in 2006. “We got into automation because there was a part that was so heavy we had a tough time physically moving the part from one machine to another. It was very taxing on our machine operators. So we brought in a robot to perform the task.”

Vickers’ first robot deployment was not without trepidation.

“We were scared to death,” says Tyler. “We thought it was going to be way too sophisticated for us. We didn’t want to maintain it. We didn’t know if it would be reliable. We thought our employees would feel threatened. And we thought there was a lot of cost involved upfront.

“But we were knuckleheads. It turned out to be the best thing we ever did and it happened very quickly. Our cost structure changed overnight.”

Although improved ergonomics was the original goal, the additional benefits of automating proved a welcome surprise.

“Instead of having three people in the cell, we only needed one,” says Tyler. “Instead of our throughput being inconsistent day to day because of labor and the fatigue factor in the cell, it was consistent. It was faster!

“The biggest impact, though, was safety-related. It didn’t take much to realize that this was a safer process. Our people actually gravitated towards the cell. It was less taxing on them and clearly higher tech, which is more fun than what they were previously doing, manually loading and unloading the cells.”

As Tyler notes in this ‘Why I Automate’ episode shot on Vickers’ shop floor, they now attract workers that aren’t just looking for a paycheck, they’re looking for a career.

Contrary to popular myth, robots are not only workforce multipliers, they lead to workforce satisfaction. Robots are cool and they attract cool people.

For a small manufacturer on the East Coast, it wasn’t so warm and fuzzy. Automation meant do or die.

Automate or Else

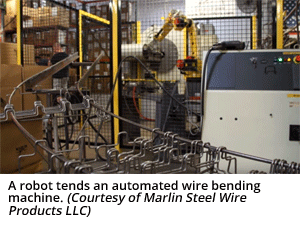

Ranked by Inc. magazine in the top 200 fastest-growing private manufacturers in the U.S., Marlin Steel makes custom-engineered steel wire material handling containers for the aerospace, defense, medical and automotive industries. This non-union shop located in Baltimore, Maryland, boasts seven-fold revenue growth since 1998. They did $5.5 million in sales in 2014.

But it wasn’t always this rosy. Marlin Steel’s story is the traditional model for automation adoption.

But it wasn’t always this rosy. Marlin Steel’s story is the traditional model for automation adoption.

“When I first bought the company, every bend, every cut, every weld was done by hand,” says Drew Greenblatt, President of Marlin Steel Wire Products LLC. It was straight out of a Charles Dickens novel, where two guys didn’t have eyes, three guys didn’t have fingers.”

The one-time bagel basket manufacturer was an archetype for dull, dirty and dangerous work, the kind that might make “the hands” in Dickens’ tales shudder.

“We had eight guys whose sole job it was to hand-bend wire. They did about 300 bends an hour for 8 or 10 hours a day. These guys had big right arms from doing the same thing over and over again, sometimes for years. It was mind-numbing work.”

Faced with insurmountable competition from China and the low-carb diet craze spoiling demand for bagels, Greenblatt would transform his shop floor, the caliber of his products and workforce, and the market demand for his metal containers. For Marlin Steel, it wasn’t a question about ROI. It was about survival.

In this ‘Why I Automate’ episode, see how Marlin Steel is not only surviving, but thriving thanks to automation and robotics.

“The alternative was extinction. There’s no future in hand-bending bagel baskets,” says Greenblatt. “Every other day, we get a flyer for an auction for a company that’s gone out of business. You either get the best state-of-the-art technology or ultimately your company will go away. It may not be next week, but it’s going to be soon. You cannot survive in today’s world without a heavy investment in automation and technology.”

A midsized Canadian shelving manufacturer knows this all too well. They were experiencing some of the same competitive challenges as the bagel king of Baltimore. Automation and robotics was inevitable. As they saw it, there was no alternative.

The Price War

Based in Montreal, Etalex manufacturers shelving and racking systems for use in retail displays, commercial furniture, and storage systems for warehouses. In business since 1966, the turning point for Etalex came in 2004, when they integrated their first robot. For them, it was all about increasing production and reducing costs. They were getting pummeled on price.

“Without automation, we would not be running right now. It’s the key to our success,” says Jean-Francois Rousseau, Plant Engineer for Etalex. He oversees the factory’s automation, IT, and maintenance groups.

“Without automation, we would not be running right now. It’s the key to our success,” says Jean-Francois Rousseau, Plant Engineer for Etalex. He oversees the factory’s automation, IT, and maintenance groups.

“We have a good product and great salesforce, but the competition is very hard. To stay competitive we had to cut our prices by half. But the steel price increased, the employees’ salaries increased, so the only way to keep selling shelves (at a price the market will bear) is to automate.”

Etalex has 29 robots in 19 robotic cells, most populated with FANUC robots. They do a variety of tasks, including palletizing, assembly, press tending, MIG welding, spot welding and machining. He says they use FANUC’s integrated vision on eight of their robotic cells for quality inspection and robot guidance.

“Inside those robotic cells there are many operations,” says Rousseau. “On just one robotic cell, I do assembly, spot welding, press tending, palletizing and quality check.”

With automation, Etalex is able to keep its production costs down and profits up. It’s also allowed the company to expand the market for its shelving systems.

“Before we only had the Quebec market,” says Rousseau. “In the last couple of years, we can sell to Ontario and the U.S., so the automation helped us to reduce the costs and be competitive. We can be more aggressive on price.

“If we didn’t automate, I’m sure we would have been closed right now.”

Bridging the Skills Gap

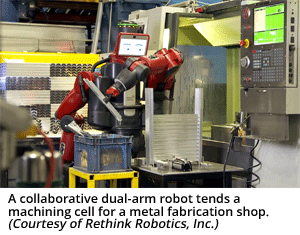

A metal fabrication shop primarily serving the office furniture market wasn’t worried about going out of business, for they have an 85-plus-year history of adopting advanced technology and progressive manufacturing methodologies. Their concern was about people. Specifically, the lack of them.

Rapid-Line Inc., a contract manufacturer in Grand Rapids, Michigan, with 165 employees, turned to robots because they couldn’t find people. Desperately seeking skilled welders and seeing no bridge in sight for the ever-widening skills gap, Rapid-Line acquired its first robot from Yaskawa Motoman in the early 1990s.

Rapid-Line Inc., a contract manufacturer in Grand Rapids, Michigan, with 165 employees, turned to robots because they couldn’t find people. Desperately seeking skilled welders and seeing no bridge in sight for the ever-widening skills gap, Rapid-Line acquired its first robot from Yaskawa Motoman in the early 1990s.

Now this employee-owned shop has 11 Motoman robots on the shop floor doing welding, machine tending and plasma cutting. In addition to robotic MIG welding, they recently started TIG welding with robots.

We first met Rapid-Line last fall when we introduced you to a new technology for robotic welding called Kinetiq Teaching, profiled in Robots Fill the Welding Gap. Developed by Yaskawa Motoman in partnership with Robotiq, a Canadian manufacturer of innovative robotic grippers, Kinetiq Teaching speeds up the programming time for small and medium-sized businesses by making the robotic welding process simpler and more intuitive for shop floor personnel.

This video demonstrates how easy it is to “show” a robot how to weld with Kinetiq Teaching.

An early adopter of the technology, Rapid-Line has used Kinetiq Teaching for about a year and half now to speed weld set-ups for their high-mix, low-volume production. Lot sizes are typically only 40 pieces, so they needed a flexible solution.

Mark Lindquist, Rapid-Line’s President, thinks it’s important to stay a step ahead. Sometimes that means trying new and emerging technologies.

“If you wait for it to be proven, you’ll be at the end. I can’t afford to play catch up.”

He says with sales around $24 million, Rapid-Line can afford to do some R&D and should be undertaking it at this level. They also recently purchased an Amada automated press brake, which coincidently uses a Motoman robot.

“It’s a dramatic step up in press brake automation. We have the second one that came into the country,” says Lindquist. “It basically does the same things or better than a human operator. (He says it actually takes the place of two operators over a couple of shifts.) Plus it doesn’t take breaks, it doesn’t have insurance, it doesn’t have bad days, and it doesn’t argue with the foreman. The uptime is significantly better than a human.

“We’re trying to be less dependent on labor, mainly because we just can’t find skilled people.”

Lindquist says they use their assembly robots on some of their higher volume lines and that frees up labor for more specials and low-volume jobs. This is a recurring theme among successful SMEs. Automation and robots help them grow into different applications and new markets.

Automation Fuels Market Expansion

Vickers Engineering grew from a local machine shop into an advanced production facility with Tier 1 status.

“We are a precision machining company,” says Tyler. “That is typically an old school industry and populated by a lot of smaller companies that compete on a contract-basis. Traditionally, it’s very difficult to break into that proverbial ceiling of production work, which is what a lot of the OEMs do for themselves. We had the ambition to be more than just a job shop. To do that we needed to chase some volume-oriented platforms. That led us into automotive. But we recognized pretty quickly that in order for us to compete in this market, we have to be creative.”

It didn’t hurt that Vickers is within 200 miles of the Motor City, located on the southwest side of Michigan, just north of the Indiana border.

It didn’t hurt that Vickers is within 200 miles of the Motor City, located on the southwest side of Michigan, just north of the Indiana border.

“We implemented automation in a couple different areas where we needed the help, from a cost standpoint, to eliminate some need for people,” explains Tyler. “It went from a person running two machines to a person having the ability to run a minimum of three and maybe as many as six machines. That instantly helped our cost structure.

“Now, bear in mind, we found ourselves in a high-volume environment that required three shifts. We would have long runs, sometimes years. That all aided in the justification of setting up automation because you can amortize your costs relatively quickly. Where it gets tricky is in those lower volume environments.”

Return on investment is not as tricky as it might sound. But it does usually require a long-term outlook. Get the facts and figures in Calculating Your ROI for Robotic Automation: Cost vs. Cash Flow.

With automation, Vickers was able to expand their reach in the automotive market to where they’re not only a Tier I to their largest customer, Toyota, but they’re also a Tier II to other large automotive OEMs. Their other big market is oil and gas, where they make fluid control products like valves, pipes and fasteners.

“Automation was the single, biggest driver in the change to our business. Had it not been for automation, it’s tough to envision what kind of company we would be. I can tell you we would be significantly smaller and have less of an impact in the market. We would not have been competitive in automotive if it had not been for automation.”

No longer just a local job shop, Vickers has $40 million in sales and growing.

“We used to have a lot of local customers. But not anymore,” says Tyler. “Now we ship all over North America.”

From Commodity to Value-Add

Vickers isn’t the only SME tapping into new markets. Marlin Steel transformed itself from a low-tech, commodity operation into an exporter of high-precision, highly engineered products for Fortune 500s. And they did it by investing millions in automation and advanced technology.

“There are a lot of people that are sitting on the sidelines because they are worried about the economy and the future,” says Greenblatt. “You’re going to have to be a whole lot more worried if you don’t invest back into the business, because you’re becoming more of a dinosaur.”

Warding off bankruptcy himself, Greenblatt brought in FANUC robots and various pieces of hard automation to forge a new beginning for Marlin Steel.

Warding off bankruptcy himself, Greenblatt brought in FANUC robots and various pieces of hard automation to forge a new beginning for Marlin Steel.

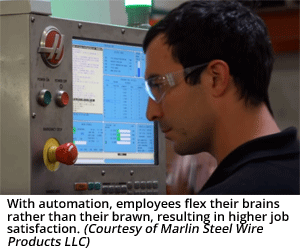

“With this strategy, our employees are like supermen. We’re giving them all kinds of tools that make them very productive. Some of it is automation for bending, welding and cutting, and then we have other automation like the FANUC robots that do the loading and unloading. The employees are outside the (robot) cage and very safe.”

Greenblatt can’t stress the safety factor enough.

“We’ve gone more than 2,504 days without a safety incident. I attribute a lot of that to our commitment to automation and robotics. It’s a huge benefit of robots that is often overlooked. Robots do the carpal tunnel syndrome work and humans do the brain work.”

He says now his workers are doing interesting tasks rather than the same, boring jobs all day long.

“Now the guys are dealing with all the sophisticated elements, the set-ups, the quality checks, the in-process inspections, tweaking machines.

“It’s a different world doing manufacturing with the right tools and state-of-the art technology,” says Greenblatt. “In the old days when we would make something, an export to us was shipping from Brooklyn, New York, to the Bronx. Last week, we exported wire forms to Argentina, Canada, Mexico and Austria. We export to 39 countries. That would never have happened without robots.”

Marlin Steel is running four shifts, on the weekends, and with lights-out automation.

Better Consistency, Better Quality

Improved quality and precision are also major drivers in Marlin Steel’s success and thriving export market.

“We were in the bagel basket market, where our clients did not own a tape measure. If you can hold the bagel, it’s a quality success story,” says Greenblatt. “Now we sell to Boeing, Merck and Pfizer, to Toyota. They need precision (+/- 0.1 mm). We could never hold those kinds of tolerances with a guy bending by hand. You need the robotics and automation to have exceptional quality.

“We got our biggest order in our company’s history about two weeks ago, from a Japanese company,” says Greenblatt. “This only happened because we have very tight tolerances. Japanese companies are extremely quality-centric. Our engineers came up with some really innovative ideas to knock their socks off.”

Vickers’ CEO credits his robots’ consistent repeatability for a quality score of 4 PPM (parts per million).

“That means for every 1 million parts that we ship, we have four questionable parts,” says Tyler. “That’s a world-class level score. And we think we can better it. Automation has allowed us to migrate to that level of consistency.”

Robots Create and Save Jobs

Automation also creates jobs. Debunking the myth that robots are job killers, the Association for Advancing Automation recently published a white paper providing facts, figures, and real-world examples supporting what many have said all along, that robots save jobs and create jobs. This article provides a good synopsis and a link to download the white paper.

“When we win an opportunity,” explains Vickers’ Tyler, “not only does it create jobs here in our facility, but as a Tier 1 we’re buying the raw material, which in our case is typically castings made by foundries, all of which we’ve bought from in the United States. There are lots of jobs upstream from us, from the foundry jobs to the trucking and logistics people that have to get it across the country, to the painting company where the part is first painted, then we machine it, and ship it out again. There are a lot of jobs in that supply chain that were created because we were competitive, and the only reason we were competitive was because of a FANUC robot sitting in the middle of a cell.”

Robots not only create jobs, they create better jobs. Jobs with higher pay, better working conditions, training, benefits, and just a higher level of overall job satisfaction.

“The notion that robots are job killers is nuts,” says Tyler. “If it’s a job killer for anybody it’s for the offshore competitors. But the fact of the matter is it’s propelling our economy. It’s absolutely creating jobs in the United States.

“The employees we’ve brought in, let alone the employees that are still in the building, are a completely different makeup of pay scale and experience,” he says. “Our payroll is significantly larger today. Part of that is because of the sophistication of work that is required with automation. There are a significant number of jobs in this building that are due directly to our adoption of automation.”

Vickers has about 150 employees. At its peak, the company had 185, according to Tyler. He said the decrease is due to the downturn in the oil and gas industry earlier this year.

“With oil and gas coming back and additional automotive and other industry growth on our books for the next five years, or additional jobs that we’ve won that will also be automated, we expect to have record years again in 2016 through 2020.”

Not Just Jobs, Better Jobs

As you saw in the earlier video, Marlin Steel’s automation ramp is also fueling job creation. And it’s creating not just jobs, but rewarding careers with full benefits.

“When I bought the company, the prior owner paid the employees minimum wage,” says Greenblatt. “Now we’re paying three, four, or five times that depending on the role. By us investing in them, our employees become more valuable and more indispensable. When I met them, their health insurance plan was to go to the emergency room. They had no retirement plan. Now they have the same health insurance plan I’m on.”

And Marlin is still hiring. Yet, he faces the same challenges other business owners are experiencing, struggling to find skilled talent to fill welder and robotic set-up jobs.

“We have over 30 employees and eight temps, and we’re in the process of hiring eight more people. We have 25 percent unemployment just a mile away, but we have eight jobs at $24 an hour and haven’t been able to fill them. Plus health insurance, 401K, holidays, all of it. It’s a real job, a career.

“And these eight hires will create all kinds of ancillary jobs,” adds Greenblatt. “The guys loading the boxes for them, the guys moving things around on their behalf. But you can’t hire the ancillary guys until you have the eight core guys. It’s very frustrating.”

It’s the same frustration Rapid-Line’s Lindquist spoke about. He’s also hiring, but having difficulty finding the right skillsets.

In-House Automation Expertise

Another common theme among SMEs that embrace automation and robotics is a tendency towards in-house integration. These companies credit their in-house capabilities for much of their success and continued growth.

“We have a family of parts of two different commodities (automotive and oil & gas),” says Vickers’ Tyler. “It’s not the same part number day after day, but it’s the same type of part, just different sizes and different part numbers. We’ve been able to develop automated cells that can recognize the difference in the parts, hold the differently sized parts, and perform the task. We’re not developing anything that’s new or different per se, but it is relatively different for a company of our size to be so progressive.

“What’s made us unique is that we’ve now developed a fully functioning integration team that can take an automation project from start to finish, and without any outside help. No consultants. No integrators. We do everything in house.”

Tyler says that over the years they’ve managed to develop a standardized automated cell.

“Regardless of the industry or the part, there’s a particular look, feel and efficiency around how we design the cell,” says Tyler. “That’s all a credit to our automation team.”

Vickers isn’t the only small shop going it alone. This video shows how a motorcycle clutch manufacturer kept their labor costs in check by automating several machining cells with ABB robots, all in house.

Etalex has also been doing its own robot integration since the first installation in 2004.

“It took about a year to integrate our first robot,” says Rousseau. “Then we installed a second cell in 2005, another one in 2006, and then another one in 2007.”

Rousseau says they were installing about one cell a year through 2011. Apparently, once they realized the benefits, they were hooked! After the first several years, with accumulated experience, they increased their integration speed and were installing up to three cells a year.

“We do everything from scratch, all the electrical and mechanical, everything. Sometimes the robot is installed on a rail. We build the rail here and do all the programming here.”

He says along the way they had to hire new workers, including skilled electricians and mechanical engineers to support the robotics. But the overall number of employees remained about even throughout the automation ramp-up. Where robots replaced some operators in the production department, the number of employees in the automation group grew.

Currently, Etalex has about 150 employees with 46 of those in the production department. Employee reaction to the robotics ramp-up was mixed. Rousseau says while the maintenance group was excited for the new robots, the production department was a bit apprehensive in the beginning. But over the last decade, the production folks have learned to like the robots as well.

“Now, when they think of a new task to automate, they share that idea. There are two types of guys on the production side. One type takes care of the robot and maybe operates two or three robotic cells. Then there are the other employees who don’t take care of robots. The guys who operate the robots are more confident of their job security, so they want to make their robot as productive as possible.”

“Now, when they think of a new task to automate, they share that idea. There are two types of guys on the production side. One type takes care of the robot and maybe operates two or three robotic cells. Then there are the other employees who don’t take care of robots. The guys who operate the robots are more confident of their job security, so they want to make their robot as productive as possible.”

Rousseau says the challenge of integration isn’t the robot. It’s the process.

“To program a robot is easy. But to understand the process, the product, and the quality requirements, it’s harder for an external integrator than it is for us. The key to our integration success is that we do it ourselves and we continue to improve the automation. Sometimes we need a touch up on the program, or do an improvement or repair, and it’s easier for us because we built it.

“Return on investment is difficult to determine, but it’s about two to three years,” he says. “Here in Canada they also give us a good R&D tax rebate.”

Rousseau is referring to the Canadian government’s Scientific Research and Experimental Development (SR&ED) Tax Incentive Program, which provides incentives to companies of all sizes to undertake research and development.

Collaborative Robots a Boon for SMEs

In 2013, while attending the Automate show, Rousseau came across a new type of robot designed to work in close proximity to humans without the need for elaborate safety fencing. The collaborative robot was the UR from Universal Robots, a Danish-bred robot manufacturer recently acquired by Massachusetts-based automatic test equipment giant, Teradyne.

Rousseau was particularly interested in the space-spacing features of the UR robot.

“We didn’t need the security guard all around it. That was the main factor. It also reduced the integration delay and cost. We didn’t have to build all those guards around the machine and connect the safety switches.”

Now, three UR robots are tending machines at the end of three different production lines at Etalex. They remove finished parts and palletize them. Check out this video to see one of the cobots on the job at Etalex.

To learn more about collaborative robots, or cobots, you can check out this article on the subject.

Etalex isn’t the only SME to embrace this new era in industrial automation. Rapid-Line also took the plunge with collaborative robots.

Can’t Find Workers? Hire a Cobot

Never one to shy away from new technology and innovative ideas, Rapid-Line introduced a humanoid robot to their production floor this past January. At the urging of their largest customer, Steelcase, the forward-thinking shop purchased two Baxter collaborative robots from Rethink Robotics.

“We see this collaborative robot technology coming on real strong,” says Lindquist. “We recognize that these collaborative robots are going to change the nature of robotics, so we wanted to be on the leading edge of that. We want to understand how they work and how they fit into our operation.”

“We see this collaborative robot technology coming on real strong,” says Lindquist. “We recognize that these collaborative robots are going to change the nature of robotics, so we wanted to be on the leading edge of that. We want to understand how they work and how they fit into our operation.”

You can see Baxter on the job at Rapid-Line in this video.

Lindquist stresses that Baxter is very different from the nearly dozen traditional robots in residence on Rapid-Line’s shop floor.

“The Motoman will do a discreet operation and will do it very precisely and with a heavier payload,” he says. “It will put the parts exactly where you want them. Whereas with the Baxter robot, we’re finding it’s more an addendum to a person.”

The Baxter robots at Rapid-Line are sharing the machine-tending tasks with their human coworkers.

“A person might be doing a more complex part of a task and then the Baxter works in conjunction with the person to put the parts in the assembly fixtures,” explains Lindquist. “Then Baxter hands it back to the person to again do the more complex work.”

He says it took some time for Baxter’s human coworkers to adjust. To recognize Baxter as a tool and not a toy.

“That’s one of the reasons we decided to try Baxter to test that reception,” says Lindquist. “We found that in the cells where we’re using Baxter, we basically assigned the operator to the machine and they became partners. That proved to work out much better. They took ownership of the Baxter robot, recognizing that it won’t do it all but it does take care of the repetitive tasks that they previously had to do themselves.”

Several other unique features often associated with this new breed of cage-free collaborative robot also took some getting used to. Lindquist says programming with the arm throws people for a loop at first.

Rather than programming the robot through a teach pendant, Baxter is taught by leading the robot through the desired movements. This video demonstrates how easy it is to teach Baxter a task.

“No enclosure around it gets some people apprehensive,” adds Lindquist. “You have to prove to everybody that it’s safe. The other thing is the accuracy isn’t the same, so you have to use dedicated air cylinders to move the part into final position. The payload is quite a bit less as well, so it’s not going to be a replacement for a material handling robot.”

Lindquist says automation isn’t the end-all and attributes Rapid-Line’s growth to a number of factors. This recent article sheds some light on the other forces at play in Rapid-Line’s continued success.

“It’s like comparing your automobile from 1975 to the one you have today,” says Lindquist. “You’re still getting down the road, but it’s a dramatically different ride today with sensors, capabilities and options that you didn’t have back then.”

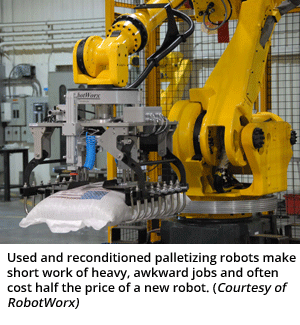

Why Used Robots Make Good Sense for SMEs

Rapid-Line secures some of its advanced technology by being clever about how they purchase it. Used technology can be just as good as new.

“As of late, we’ve been buying a fair amount of reconditioned robots,” says Lindquist. “That’s worked out pretty well for us. You get a robot for about half the price of new. In our environment where it’s not high volume and it’s not automotive production line stuff, it doesn’t have to run real fast and it’s still as reliable as a new one.”

Rapid-Line purchased their reconditioned Motoman robots through RobotWorx, a specialty integrator in Marion, Ohio. RobotWorx sells ABB, FANUC, KUKA, Yaskawa Motoman, and many other robot brands, both new and reconditioned models. They also integrate complete turnkey cells with reconditioned robots, and sell hybrid cells using a mix of reconditioned robots with new equipment.

Check out this video demonstration of a hybrid MIG welding cell using a reconditioned ABB robot with new components for a turnkey solution.

“Most of the (used) robots we sell are three to five years old, says Keith Wanner, Founder of RobotWorx, which was acquired in 2014 by Scott Technology Ltd, a New Zealand-based integrator. “There really haven’t been many changes to robots in the last five years. They’ve evolved to the point where all the manufacturers’ arms are almost equal in terms of reliability and quality.

“They make them to handle automotive-type manufacturing at 100 percent speed, 7 days a week, 24 hours a day,” he says. “So the robots are built to last.”

Good as New, Half the Price

Wanner says that’s a major benefit to smaller companies that can still take advantage of the robot’s longevity without paying the higher upfront cost of a new model.

“Most small to medium-sized companies, they use the robot for one shift, 5 days a week,” he says. “They might use a robot that’s capable of holding 100 pounds to hold a little weld gun that’s five pounds. So that robot is only working one shift and holding five pounds, and probably running at a slower speed. That robot will last 25 years in a small shop. But they may only need the robot for 3 hours a day, so they don’t want to spend $100,000 for new robot system. But they will spend $40,000.”

He says the price difference is usually 40 to 60 percent of new. But what about the integration costs, which most automation veterans agree account for the majority of a robotic system’s cost? Wanner says that’s where smaller shops can really save big.

He says the price difference is usually 40 to 60 percent of new. But what about the integration costs, which most automation veterans agree account for the majority of a robotic system’s cost? Wanner says that’s where smaller shops can really save big.

“Forty percent of the time when we buy a robot system from somebody, we’re buying the whole system,” says Wanner. “We buy a complete welding workcell and then we recondition the whole workcell and re-sell it. That’s why it’s a lot cheaper. If it’s just the robot, you’re not saving that much. But if you can get the whole turnkey reconditioned workcell, that’s where you get the best savings.”

But how do you know your used robot is safe and reliable? Wanner says every used robot is subjected to a 168-point reconditioning process and RobotWorx backs their reconditioned systems with a warranty covering all parts and service.

“We always encourage the customer to spend a week, two weeks, a month, or whatever it takes at our facility to make sure they are comfortable with the system and that it meets all of their expectations,” explains Wanner. “We don’t want to ship any robot or system until it is 100-percent ready and we want the customer to be trained enough that they are self-sufficient. All this is very important to the overall success of the application.

“We try to build confidence for the customer,” he continues. “For example, with a FANUC robot we always make sure we have their legal software, so we’ll buy the software license from FANUC when we sell their robot. When people buy a used robot from other sources, they might find out later that they don’t have the licensed software.”

He likens it to buying a used laptop with a copy of AutoCAD on it. Then if you have problems with it, you’re out of luck because you don’t really have a legal copy of that software. With a legal copy of the robot manufacturer’s software, Wanner says the customer receives the support from RobotWorx and the robot manufacturer.

First-Time Robot Buyers Beware

“We deal with a lot of first-time buyers,” says Wanner. “They turn to the Internet to find out where to buy robots. That’s where we get a lot of our leads. But some first-time buyers turn to eBay or something like that to find a robot. They think we’ll just get a robot and make it work, like buying a band saw or something. Then they find out when they get the robot that there is a lot more to it, or the robot doesn’t work.

“At auctions they may pay more for a robot than what we would sell them for with a full one-year warranty,” he says. “They pay more and don’t even know if it’s going to work because it’s an as-is sale.”

Wanner says they get a lot of calls from companies that bought robots at auctions and now need someone to come in and get them working properly.

“That’s one thing we don’t do. We don’t do service on robots we don’t sell, because you don’t know what you’re going to get into.”

He says a lot of first-time buyers are looking for palletizing robots, like the ones shown in this video. That’s where they get the best pay-off, according to Wanner.

“Say it’s a company that makes 80-pound bags of seed and they’re difficult to handle (both ergonomically and safely). Rather than paying a person to do that all day long, we’re selling them a robot for palletizing. Or machine shops where you put a part in the machine and it takes 30 minutes for it to do its thing. Rather than having a guy standing there, they want a robot to do that monotonous loading and unloading work.

“The same with welding, because welding is a nasty job. You have the smoke and the hazards of welding. So you let the robot do those hazardous-type jobs. The robot is just another tool to make things more productive,” adds Wanner.

Exploit Technology

But how is a small company supposed to ramp up with automation without the work to support it? What comes first, the chicken or the egg?

For a small plastics fabricator, they hatched their automation plan before they had their first contract. Check out this ‘Why I Automate’ episode for the whole story.

Vickers’ CEO suggests that any company making their first foray into automation, just take the leap.

“When we win an opportunity, we quoted the opportunity with automation in mind and then we typically have enough runway to actually implement the cell,” says Tyler. “Not always. Sometimes we have to do it manually for a period of time and then implement automation on the fly.”

But he says don’t expect to have your own integration team at the outset. Seek out the expertise of a reputable automation specialist, such as an RIA Certified Robot Integrator.

“There’s always something in everyone’s facility that has the ability to be automated,” adds Tyler. “Anything with any sort of repetition could and should be automated.”

Resources for SMEs

Marlin Steel’s Greenblatt says small and midsized businesses have to shift their thinking. He suggests that SMEs educate themselves, recommending they attend the Robotic Industries Association’s biennial flagship event, the Automate show.

“The best resource is RIA’s trade show, which is an amazing event where they attract the smartest minds in robotics throughout the world and they all coalesce in one place,” says Greenblatt. “They showcase the most amazing technology. It’s a tremendous value because you can fly out and get to meet 10 or 20 vendors that will help you multiply your productivity very quickly.”

Alas, you will have to wait until spring of 2017 until the Automate show comes around again. In the meantime, a great networking event populated by many of the “smartest minds in robotics” will convene in Florida in February for the A3 Business Forum. There’s still time to register, so you can network, connect, and learn. Then you, too, will be like these successful SMEs – in the know.

Author: Tanya M. Anandan