Twitter Timeline

FourByThree proposes the development of a new generation of modular industrial robotic solutions that are suitable for efficient task execution in collaboration with humans in a safe way and are easy to use and program by the factory workers.

The project was active for three years, December 2014-2017.

−The future of industrial manufacturing and production requires highly flexible work cells that are able to combine automation with tasks traditionally done manually. But such cooperation between humans and robots in close proximity requires the safeguarding of the human at all times. As traditional safety systems like fences, laser scanners, or pressure sensitive mats are too cumbersome or not applicable for these scenarios, we have noticed a lot of development efforts by industry and academia over the past years towards sensor systems that allow a safe cooperation between humans and robots in the same work space. Many of these new systems depend on a three dimensional representation of the work space to detect intrusions of virtually established, three dimensional safety spaces. The researchers of the Fraunhofer IFF have recently developed and patented a novel sensor system that is based on projector and camera technologies and offers many advantages over three-dimensional safety systems.

This projection-based sensor system establishes safety spaces of arbitrary shapes such as rectangles, circles, lines, filled areas, or any further combinations by projecting light from a projector directly onto the environment. Violations of these safety spaces caused by disruptions to the emitted light are robustly detected by surrounding cameras. The operational principle is based on a comparison of a two-dimensional representation of the current state of the safety space and a two-dimensional, computer-generated expected (fault-free) state of the safety space. As there is no need for a complex computation of three-dimensional data of the environment, the implemented algorithms for image processing and collision detection lead to minimal reaction times of the system. Furthermore, the robustness and availability of the system is enhanced through synchronisation of projectors and cameras. Here, the cameras are adapted to the frequency of the light emitted from the projector, reducing the influence of environmental light conditions on the collision detection process.

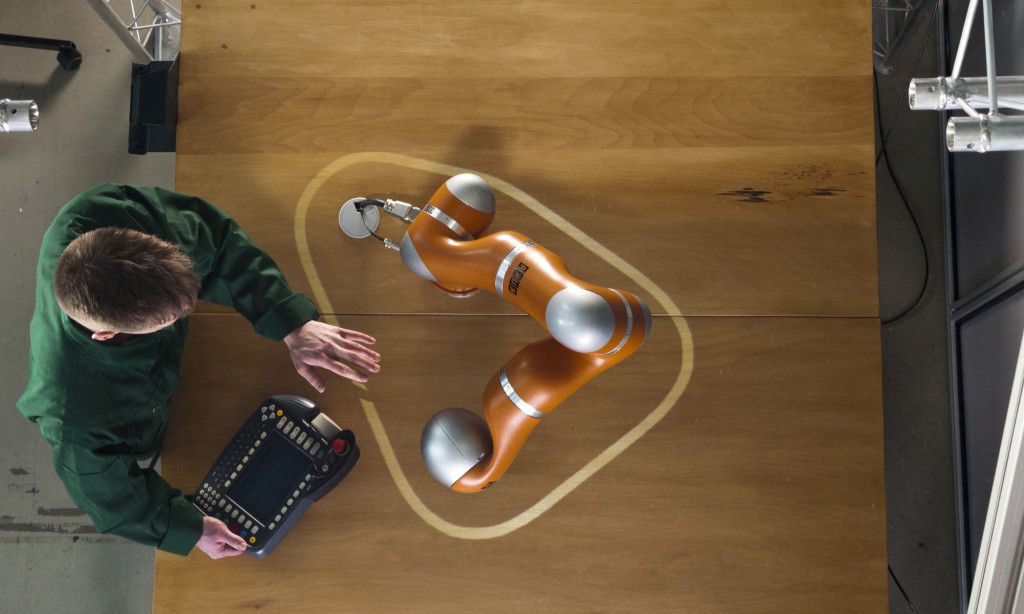

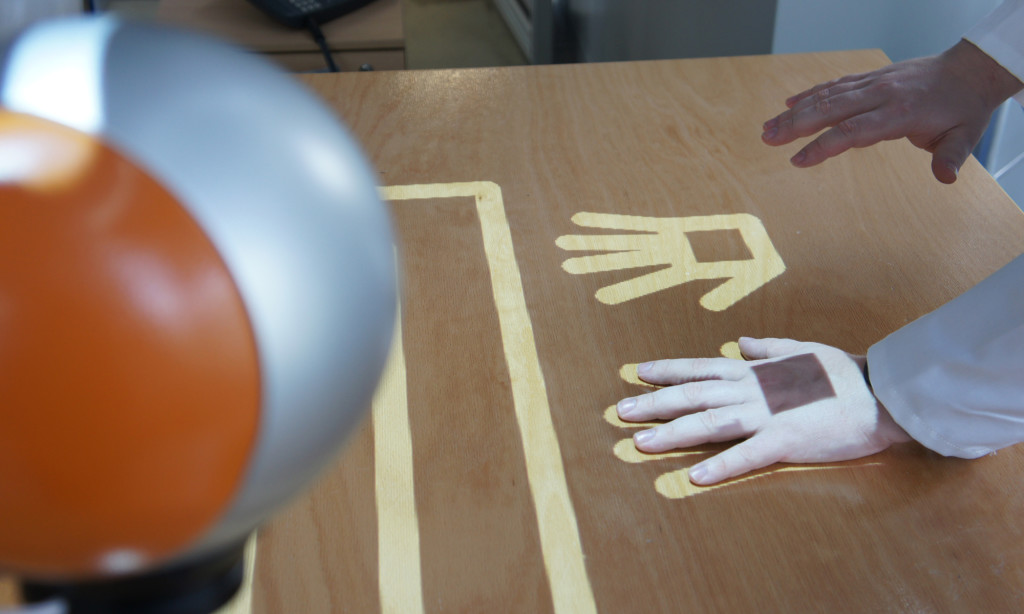

The system was initially capable of establishing several user-defined safety spaces statically in the workspace, and it was possible to switch between them manually or automatically. The next development step included the adaption of the sensor system to a human-robot application and the dynamic generation of the safety space generation based on the robot’s movement. This research was done within the ECHORD [1] experiment “Experimental Evaluation of Advanced Sensor-Based Supervision and Work Cell Integration Strategies” (EXECELL). Here, a prototypical collaborative workplace with a KUKA LWR 4+ was built up to test the projection-based sensor system as a safety-rated speed and separation monitoring system. One projector and four cameras were used to monitor the collaboration area from multiple perspectives and a connection to the robot’s controller was established. On this basis, the system incorporated the robot’s joint angles and velocities in the safety space generation process. The resulting safety space minimally enclosed the robot at all times and left a maximum area of the workspace to the user. Figure 1 shows the collaborative workplace with the KUKA LWR that is enclosed by the dynamically generated safety space (white line).

In the project “FourByThree” we will advance these predevelopments and deploy this technology for applications in real industrial environments. For this, the projection-based monitoring system has to be adapted according availability, safety, and modularity to meet the requirements of various industrial conditions. Beside technical improvements that include the enhancement of response time, detection capabilities, and robustness, the projection system should be composed of single modular projection unit that provides higher flexibility and customizability. Each unit will comprise one projector and at least two cameras that can be adjusted individually. By configuring several units to work together, it will even be possible to operate in difficult environmental conditions with low ceilings or large monitoring areas. The design and development of these projector-camera units is one of our main tasks in the project. The second task concerns the evaluation of the sensor system according a future safety certification. Thus, in cooperation with our “FourByThree” project partners we will analyse the technology using the relevant safety standards.

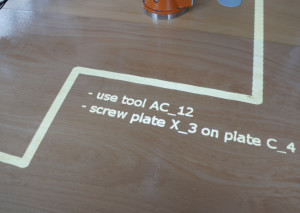

Beyond the topic of safety, this technology is also well suited for visualization to give the operator information. This means that this system can be also used to visualize process-related, robot-related, or even general information to the worker. Here it may be useful to depict some schemes for worker assistance, symbols for representing robot’s state, or text messages for describing the current task. The system can also be used to support the user in configuration and teaching during initial operation. In “FourByThree” we will enhance and apply this technology to the individual applications supporting the user at certain tasks. In Figure 2 are some examples of assisting the user by visualizing different types of information directly on the table top.

|

|

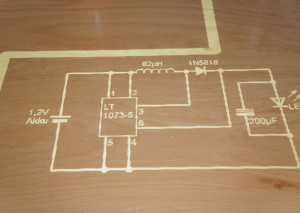

Another exciting feature of the projection system concerns the possibilities for human – machine interaction, whereby the operator can offer input and information back to the robotic system. This means that the projection system is capable of providing buttons or simple menus which can be used to control the robot, task, or process. The shape of these interaction areas and the reaction upon triggering can be configured individually. So for instance the interaction system allows the confirmation of a finished task, the execution of a certain process or the choice of a special task configuration. Figure 3 shows a two-hand interaction area that has to be triggered to continue the robot’s motion after a safety violation.

These developments are all made with an eye to future industrial deployment, and we look forward to testing the possibilities and showcasing the potential of novel, projection-based workspace monitoring system within the FourByThree project.

[1] “European Clearing House for Open Robotics Development”, Grant Agreement Number 231143

We are happy to announce FourByThree will be hosting a wokshop on human-robot interaction at IROS 2015. The workshop will focus on safety for human-robot interaction in industrial settings and will take place at Congress Center Hamburg (CCH), on October 2nd 2015.

Speakers will deal with existing safety standards and the best technologies to achieve safe robots, as well as the characteristics required to ensure safety regarding controllability, stability and force/torque transmission. The human perspective will also be taken into account, and use cases from real industrial scenarios will be presented.

The call for papers is still open. You can learn more about the workshop at fourbythree.eu/iros2015

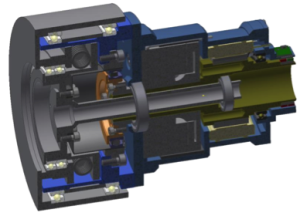

As it is the case in many projects, the initial idea for the FourByThree project came from a brainstorming discussion, in this case, between the project coordinator Iñaki (Ik4-TEKNIKER) and myself. I mentioned that we had just recently developed a new generation of actuators (see Fig. 1) for our exoskeleton in the frame of the project CAPIO (funded by the German Federal Ministry of Research and Education, BMBF, from 01.01.2011 to 31.12.2013). Those actuators had the distinctive feature – in comparison to our previous actuators [1] – of including a mechanical spring in series with the motors [2], thus creating a so-called Series Elastic Actuator (SEA), more especifically in this case, a rotary SEA. In the case of CAPIO, the idea behind it was to be able to measure the joint torques in a relative easy and compact way in order to implement a high-fidelity dynamic control of the exoskeleton system and be able to monitor the maximum torques (for safety reasons). The mechatronic design and its control (a cascade torque / speed control with a flatness-based feed-forward control) worked very satisfactorily and at DFKI we started thinking of using the same principles for building a robot manipulator safe for human-robot cooperation.

As previously mentioned, the actuators developed in the project CAPIO were not primarily designed as a direct safety mechanism, but as a measurement device. Nonetheless, the fact of being able to measure joint torques allows to monitor their values, thus indirectly providing some inherent level of safety. However, in the project FourByThree, the initial idea was to review the CAPIO design and use it as an starting point for developing a new generation of SEAs, this time, especifically designed for human-robot interaction. In this respect, the mechanical springs should probably be ‘softer’ (have a lower stiffness) to provide a softer contact in case of undesired impact and, additionally, in case of a loss of electrical power, which would hinder other possible sensor-based safety strategies. Lower stiffness would make the actuators safer (to a certain extent), more compliant, and better for a robust and accurate force control but not so precise in positioning. Thus there is a trade-off between required positioning and force control accuracy and compliance. On the other side, and since a lightweight actuator/arm is also a desired characteristic (it decreases the inertia of the system and therefore increases the safety of the overall system), the solution being developed in FourByThree for the elastic element needs to be also light and compact.

An additional requirement used for the development in FourByThree is the possibility to easily exchange the mechanical elastic element for different applications, instead of using a variable stiffness actuator approach, whose features (online stiffness modification) might not be required in many industrial environments and would likely overcomplicate the actuator design (usually requiring a second actuator to alter the stiffness). Furthermore, we are planning to build three different actuator sizes (with torques around 30Nm, 50Nm, and 90Nm at link side) and three spring sets of different stiffness, so that the integrator can pick and mix any of the actuators / springs to build a specific manipulator for the task at hand. The maximum speed is going to be around 15rpm for all the joints, since the use cases in which such robots are going to be used do not require high speeds. Moreover, speed reduction has an important effect on reducing injuries in case of impact. By limiting by design the maximum speed, we achieve intrinsic safety also on that respect.

The current status of the design is that we are pursuing two separate developments with regard to the elastic element. After assessing and ranking a series of possible materials and solutions, we ended up with two promising solutions: option A is very interesting in terms of simplicity and novelty of the solution. However, and due to its novelty, its practical implementation and performance cannot be guaranteed or assessed at this moment without performing practical experiments. On the contrary, option B has been already implemented in other applications, thus there is more knowlegde on how it works and is a less risky option in terms of having a working solution. However, it is a more complex and, possibly, bulky design (see Figure 2). For that reason, we decided to continue both developments in parallel until we can gather more practical information about their performance which allows us to decide for one of them.

Fig. 2: Status of the design of the actuator with one of the two solutions

Fig. 2: Status of the design of the actuator with one of the two solutionsAdditionally, a search for commercial safety brakes for robotic systems has been initiated. The safety brakes are used to brake and hold the robotic manipulator in case of a power outage. This is a basic safety measure to avoid the manipulator falling (possibly with a load) and injuring a person. One of the most important criteria will be the compact size; the braking torques are not as high as usually required for those commercial brakes, so probably we will use the smallest among the ones available commercially, likely being adapted by the manufacturer to our needs. It might not be the optimal solution, but the safety brakes do not lie in the main focus of the project. However, they are an additional safety requirement according to industry standards.

[1] S. Bartsch, T. Birnschein, M. Langosz, J. Hilljegerdes, D. Kuehn, F. Kirchner, “Development of the six-legged walking and climbing robot SpaceClimber”, In Journal of Field Robotics, Wiley, Volume 29, Issue 3, Special Issue on Space Robotics, pages 506-532, Jun/2012. [2] M. Mallwitz, N. Will, J. Teiwes, and E. A. Kirchner, “The CAPIO Active Upper Body Exoskeleton And Its Application for Teleoperation” at ESA Symposium “Advanced Space Technologies in Robotics and Automation” (ASTRA), 11-13 May 2015Source: IEEE Spectrum

Sami Haddadin once attached a knife to a robot manipulator and programmed it to impale his arm. No, it wasn’t a daredevil stunt. He was demonstrating how a new force-sensing control scheme he designed was able to detect the contact and instantly stop the robot, as it did.

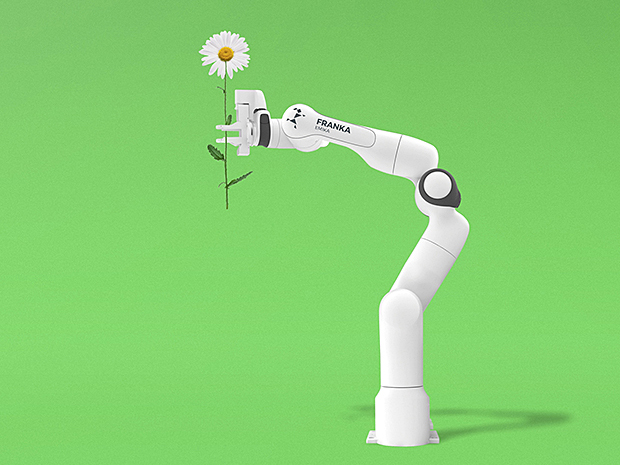

Now Haddadin wants to make that same kind of safety feature, which has long been limited to highly sophisticated and expensive systems, affordable to anyone using robots around people. Sometime in 2017, his Munich-based startup, Franka Emika, will start shipping a rather remarkable robotic arm. It’s designed to be easy to set up and program, which is nice. But what makes it special is that, unlike typical factory robots, which are so dangerous they are often put inside cages, this arm can operate right next to people, assisting them with tasks without posing a risk.

And did I mention that it can build copies of itself?

Photo-illustration: Edmon de Haro

Photo-illustration: Edmon de Haro

The robot, also called Franka Emika—“It’s like first and last name,” Haddadin explains—is not the only one ever designed to operate alongside human workers. Indeed, this type of system, known as a collaborative robot, or cobot, is one of the fastest growing segments in the robotics market, with global sales expected to jump from US $100 million in 2016 to over $3.3 billion in just five years, according to one estimate.

All the big industrial robot makers are trying to develop their own cobots, but the most innovative designs have come from startups. Rethink Robotics introduced its Baxter dual-arm robot in 2012, and more recently it unveiled a single-arm robot called Sawyer. The cobot sector, however, is currently dominated by Danish company Universal Robots, which ships thousands of robots each year. Even so, such robots remain pretty rare. Expect that to change rapidly over the next few years as Haddadin’s company—which is financially backed by a group of investors that include German robot maker Kuka—and other firms enter the market.

Haddadin, who’s worked at one of Germany’s top robotics labs and had a brief stint at the celebrated robotics company Willow Garage in Silicon Valley, says one thing that will set Franka apart from the competition is its manipulation skills. While some of its specs [PDF]—seven axes of motion, 80-centimeter reach, 3-kilogram payload, and 0.1-millimeter accuracy—are comparable with those of other robots, Franka is designed to perform tasks that require direct physical contact in a carefully controlled manner. These include drilling, screwing, and buffing, as well as a variety of inspection and assembly tasks that electronics manufacturers in particular have long wanted to automate.

Franka has more dexterity than is typical for a robotic arm because it is what is known as a torque-controlled robot. It uses strain gauges to measure forces on all of its seven joints, allowing it to detect even the slightest collisions. In contrast, most industrial robots have no force-sensing capabilities at all—and that’s why they are dangerous: They’ll take you out and won’t even notice it.

One prerequisite for torque control is an extremely detailed model of your robot’s dynamics. You need to factor in even the smallest effects, such as elasticity, vibration, and friction in the components. That’s because torque control works by comparing actual force measurements on the robot to reference values computed from a model in real time. So if your model is off, your control will be off too.

Photos: Franka Emika

Photos: Franka Emika

Haddadin saw that not as a hurdle but as an advantage. “The truth is, I model the hell out of everything I build,” he says. Gerd Hirzinger, a pioneer of torque-controlled robots and one of Haddadin’s mentors at the German Aerospace Center’s Institute of Robotics and Mechatronics, called Franka a “long-yearned-for breakthrough.”

Another factor that will make Franka stand out is cost. At the time of this writing, the robot was available for preorder at a yet-to-be-confirmed price of €9,900, or about $10,500. That’s a startlingly low figure for such a capable robotic arm. For comparison, Rethink’s Sawyer sells for $29,000, and Universal Robots’ best-selling UR5 costs even more, at $35,000.

Henrik Christensen, director of the Contextual Robotics Institute at the University of California, San Diego, says Franka is “an impressive piece of hardware.” But he adds that with cobots the main challenge is “not just the hardware but also the software to make it easily accessible to nonexperts.” Universal Robots, he says, is “beating the competition by having by far the best user interface.” So that’s an area where Franka will need to prove itself.

Haddadin says his company devoted just as much attention to software as it did to the design of the robot itself. Users can program Franka by moving it with their hands and tapping on a touch screen, with a variety of preprogrammed motions readily available. And once you’ve created a program for one Franka, you can just copy it over the cloud to one or more other Frankas.

But perhaps the most ambitious part of Haddadin’s plan is getting Franka to essentially clone itself. During initial production runs, the robot was performing about 80 percent of the work, but the goal is 100 percent, he insists. Looking further into the future, Haddadin envisions sending containers all around the world as mobile robot factories. “Inside there will be Frankas building Frankas,” he says.

Hordes of self-replicating robots popping up everywhere? For whatever it’s worth, it’s probably a good thing Haddadin is making them very human friendly—even when holding a knife.

This article appears in the January 2017 print issue as “Employee of the Month. Every Month.”

Source: Robotic Industries Association

The next generation duAro robot is designed to work alongside humans on material handling, assembly, machine tending and dispensing applications.

Kawasaki introduces the “duAro”, an innovative and collaborative robot, to the North American market to expand the breadth of applications that can efficiently and cost-effectively be automated with a robot. The dual-arm horizontal articulated robot has the flexibility to be applied to production lines with a short product cycle and frequent changeovers, and it can safely collaborate with humans in work operations. With a small footprint and low price tag, it offers robot automation possibilities to companies of all sizes.

Kawasaki introduces the “duAro”, an innovative and collaborative robot, to the North American market to expand the breadth of applications that can efficiently and cost-effectively be automated with a robot. The dual-arm horizontal articulated robot has the flexibility to be applied to production lines with a short product cycle and frequent changeovers, and it can safely collaborate with humans in work operations. With a small footprint and low price tag, it offers robot automation possibilities to companies of all sizes.

The duAro is the first dual-arm SCARA robot to operate on a single axis and features a payload capacity of 2 kg per arm. In addition to providing independent arm operation, the single axis configuration enables the robot to perform coordinated arm movements, much like a human, making it ideal for applications such as material handling, assembly, machine tending and dispensing. The use of both arms in coordinated movements increases the robot payload capacity to 4 kg, allowing for the stable handling of larger parts. The duAro is easy to install and supports flexible deployment. The base on which the arms are placed is on wheels and accommodates the controller. This enables the user to move the robot together with its base to any location desired. As the robot is designed to be installed in a single-person space, it can be deployed without modifications to the assembly or manufacturing line, or fit into confined spaces.

Safe by design, the robot’s low-power motors, soft body, speed and shared work zone monitoring allow for the duAro to collaboratively work with humans. In the unlikely event of a collision, the collision detection function instantaneously stops the robot’s movement. The duAro robot is not only safe but it is also easy to operate. The direct teach function allows the user to teach the robot tasks by hand guiding its arms. In addition, the robot can be programmed using a PC or tablet terminal by entering numerical values indicating the direction and distance of each movement.

The duAro’s innovative design, collaborative operations, ease of use and deployment herald an era of new robot applications. To further support a wide range of applications, it delivers the first-rate ±0.05 mm repeatability of non-collaborative industrial robots without the costs incurred from safety guarding solutions required with their use.

Witness the dawn of a new robot revolution in which humans and robots collaborate to take manufacturing to new heights!

Download the Kawasaki Dual-Arm SCARA Robot brochure.

Main Specifications