Twitter Timeline

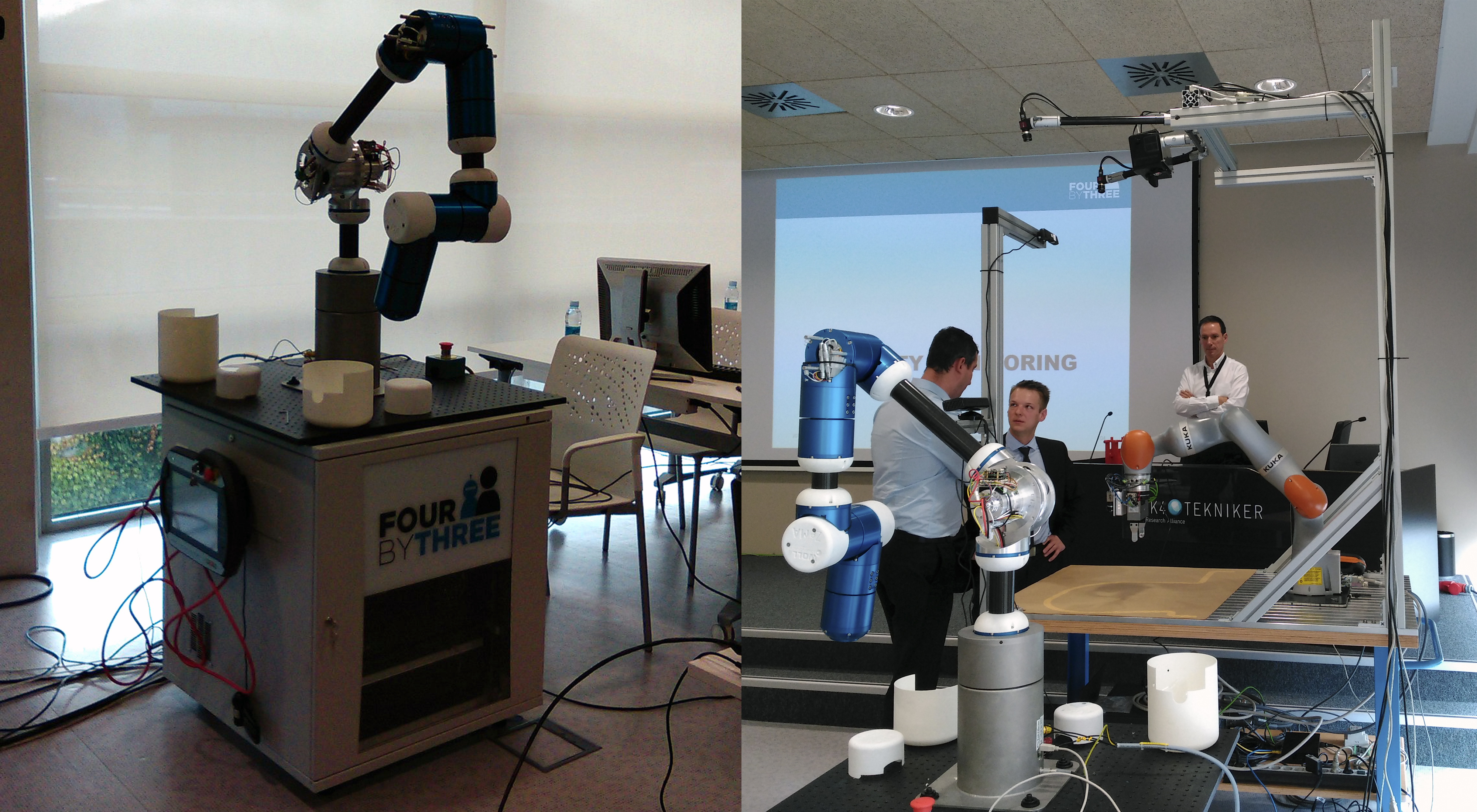

FourByThree proposes the development of a new generation of modular industrial robotic solutions that are suitable for efficient task execution in collaboration with humans in a safe way and are easy to use and program by the factory workers.

The project was active for three years, December 2014-2017.

−Yesterday, July 21 2016, FourByThree’s Mid Project Review Meeting was celebrated at IK4-TEKNIKER’s headquarters in Eibar, Basque Country, Spain.

Instead of presenting each of the workpackages separatedly, the agenda was scheduled around the main areas of the project: modular design, actuators, programming framework, safety aspects, interaction, control and non-technical issues like the status of the four pilot scenarios, dissemination, exploitation and administration.

Current status and foreseen activities were discussed for each of the topics. The technical explanations were followed by a live demonstration with FourByThree’s hardware and software components. FourByThree’s most recent prototype, which has 6 degrees of freedom, was also officially presented at the review meeting.

The meeting was attended by the project’s technical advisor, Mr. Sasa Jevtic, who congratulated the team on the work that has already been carried out and suggested some ideas for a successful exploitation strategy.

The meeting was attended by the project’s technical advisor, Mr. Sasa Jevtic, who congratulated the team on the work that has already been carried out and suggested some ideas for a successful exploitation strategy.

You can check our Twitter feed for more information on the meeting: @fourbythree_PRJ

The last few months have been quite busy for FourByThree, since we have attended three important events in the industrial sector: Technishow (Utrecht, The Netherlands, March 15-18), BIEMH (Bilbao, Spain, May 30-June 4) and Automatica (Munich, Germany, June 21-24). In the three of them we’ve had many conversations with people working for industrial companies, robotic companies or research institutions, among others.

In the case of Technishow (in collaboration with STODT) and BIEMH (IK4-TEKNIKER) we organized demonstrations where attentants had the opportunity to work with a robot in a collaborative way, performing different tasks: pointing, collaboration and manual guidance. Participants then gave us feedback by answering a questionnaire. Although data is still being processed, the first results seem to be very positive. In the BIEMH, project partner PILZ also organized a seminar on human-robot collaboration, with the participation of Universal Robots and FourByThree. All seats were booked before the event, another sign of the increasing interest in collaborative robots.

In Automatica, FourByThree was present in different stands, since several project partners had their own booth. The “official” booth was shared with two European projects on collaborative robotics, RoboPartner and and Liaa. The first hardware kit and a 5 DoF robotic arm created out of these modular components were available for visitors to see and touch. The modularity of the proposed robotic solution generated much interest among visitors, who wanted to learn more about the robot’s payload, configuration options, safety systems, as well as the scenarios where it’s being tested.

In conclusion, the fairs are a very relevant showcase for FourByThree, as well as a great source of information for the project.

FourByThree will present its innovative approach to the production and design of modular, safe and efficient collaborative robots for industrial settings.

The European project FourByThree will be present at Automatica trade fair in Munich, June 21 to 24, 2016. FourByThree will display the most relevant components of the modular, safe and efficient robotic solutions that are being developed within the project. The first hardware kit and a 5 DoF robotic arm created out of these modular components will be available at the fair. Based on this concept, four new arms with different kinematics will be built and validated in four industrial scenarios in the upcoming months.

The vision of the project is that system integrators or end-users can create their own custom robot, according to their application’s needs (“kit” of hardware and software). The results will include the hardware elements and software components for controlling and programming the robot, as well as different interaction mechanisms. One of the key components of the solution, a projecting system used for speed and separation monitoring and for interaction purposes, will be presented by project partner Fraunhofer IFF at Hall A4. 212.

FourByThree responds to the demand that robots used in industry do not only provide accuracy and efficiency, but are also able to ensure safety when collaboration between operator and robot is required, even when the workspace is shared. Thanks to the development of innovative hardware and software, the robotic solutions proposed by FourByThree will be modular, safe, usable and efficient.

FourByThree is an alliance made up of 15 European partners including research centres, industrial and technological companies and universities located in Spain, Germany, Italy, Finland, Holland and the United Kingdom. The project, with a duration of 36 months, has a budget of 6.9 million euros, and is partly funded by the EU within the European Framework Programme for Research and Innovation, Horizon 2020, under grant agreement n. 637095.

FourByThree at Automatica 2016: Hall B4. 402 (shared booth with Robo-Partner and Liia).

Source: The Robot Report

Whether for research, purchasing, education or in conjuncation with a family vacation, going to and attending robotics-related conferences and trade shows can provide real personal and business benefits, particularly when the venue is in a foreign location.

Here are the 35 remaining events for 2017:

Author: Frank Tobe

Source: Robotic Industries Association

Imagine a world without cars, airplanes, phones, TVs, and computers. Without many of the goods we enjoy every day. Goods we find so readily at our corner store, or at our fingertips. Poof, it’s all gone. That’s a world without Industrial Revolution.

An invention is just an idea if nobody buys it. Consumerization fueled the First (steam power), Second (electrification and mass production), and Third (computing) Industrial Revolutions. It will drive what many are calling the Fourth Industrial Revolution, where cyber-physical systems will blur the lines between our biological, physical, and digital worlds.

This next wave of exponential technological growth will be powered by artificial intelligence, cloud computing, and robotics. The kind of automation only seen in movies will now be in our homes. A wireless super-connected world with endless possibilities, but not without its perils.

Come along as we explore robotics consumerization and preview the industry insights RIA has on tap for 2017.

Costs Decrease, Innovation Increases

Released in October, the 2016 edition of the U.S. Robotics Roadmap (summarized here along with a link to the report) explores the possibilities and challenges ahead. It addresses the effects of consumerization. As noted, when advanced technologies are introduced into the vast consumer market, costs decrease and the pace of innovation increases. We saw this with personal computers and mobile phones.

Now robots, made smarter by enabling technologies like sensors and AI, are on the cusp of consumerization. And with it comes new and unanticipated players in the robotics arena, not your traditional industrial automation companies.

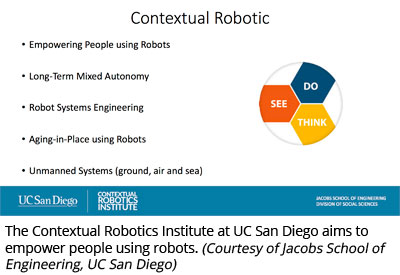

Henrik Christensen, one of the most influential robotics researchers in the world, and Director of the Contextual Robotics Institute and Professor of Computer Science and Engineering at University of California San Diego, led more than 150 researchers across the nation in authoring the latest edition of the Robotics Roadmap. Christensen notes how these nontraditional players will shake things up, for the better.

“You have companies like Amazon, Google, very different players entering into the space. If you asked 10 years ago who would be one of the big players in robotics, nobody would have said Amazon. Foxconn is saying they’ve installed close to a million robots in their electronics factories. Ten years ago, we would never have thought of Foxconn. We would have thought of them as a potential big customer, but never a big producer of robots. These companies are coming in, ignoring the established guard, and just going for it.”

New Players, New Paradigms

Christensen says the biggest market for robotics going forward may not be in traditional manufacturing. It will come from the consumer sector.

“Facebook, Google, Toyota, Huawei, they are all coming from a consumer industry. They don’t have the legacy issues. They can go after these markets without questioning whether it’s compatible with what they did last year. They don’t care. They’re used to addressing the masses. Somebody like Google doesn’t want to think about a product if they cannot sell at least one million units in the first generation.

“They are coming with a very different thought process. It will be healthy for the industry,” he adds, noting that we’ve already seen this in the service robotics industry.

“If we look at iRobot, they built a vacuum cleaner and they didn’t have to worry about whether it was a good vacuum cleaner. They didn’t have a reputation to protect. They put it on the market and it turned into a huge success. They could disrupt the market in a way that would have been very difficult for the existing companies (traditional vacuum manufacturers).

“There are a number of new players that want to become next-generation robotics companies,” continues Christensen. “Because they don’t have a legacy, they are going to do this much faster. You will see companies like GE and IBM coming into this space and trying to be very active players.”

You don’t have to look far to find the evidence. GE Ventures invested in Rethink Robotics and uses its collaborative robots on GE’s assembly lines. Amazon’s founder is also a Rethink investor, and of course, let’s not forget Amazon’s historic purchase of Kiva’s mobile robots. IBM’s Watson supercomputer has teamed up with social robot Pepper and Hilton Hotels’ concierge robot, Connie. Google (now Waymo) has been in the self-driving car arena since 2009 and is now combining cloud robotics and deep learning to teach robots new skills.

“I think the combination of games, and virtual and augmented reality is going to allow us to build user interfaces that we’ve never seen before. You’re now getting an abundance of other companies like Magic Leap (mind-blowing), Facebook, Google, and Amazon that are developing 3D vision and other advanced technologies. We’re going to see much better visual processing and much better user interfaces.”

Who could forget DORA, the head-tracking robot? Or take Pepper, cross it with Leap Motion, and you get a glass of water “somewhere else.” Check out this video.

Consumerization Drives Mass Adoption

The byproduct of robotics consumerization could be greater acceptance and adoption of robots across industries. As noted in the Roadmap, when people are accustomed to interacting with robots in their personal lives, they will be more accepting of working with them in their professional lives. They will be less likely to view robots as a threat.

The Roadmap attributes several benefits to the widespread deployment of advanced robotics and automation in manufacturing:

Another Record-Breaking Year for Robotics

These benefits are catching on. Once again, North American orders and shipments for industrial robots were up in 2016. In the robotics industry, breaking records has become almost commonplace.

With heightened interest during the recent election cycle on U.S. manufacturing and its revitalization, robotics and automation will continue to be top of mind.

Manufacturing, Healthcare, Unmanned Vehicles

Christensen says that UC San Diego’s proximity to industry will play a major role in helping Southern California become a hub for robotics development. The program’s overall focus will be on empowering humans, whether that’s in manufacturing, healthcare, or intelligent autonomous systems, their three main focus areas.

“The fact that I can see General Atomics factory from my office, and if I stand on the roof of this building I can see the Northrup Grumman facilities, makes a big difference,” he says, noting that General Dynamics and Boeing also have facilities in Southern California.

“My position here at UC San Diego is partly sponsored by QualComm. For that reason we have a very strong aerospace interest. But we also have a very strong biomanufacturing sector with gene sequencing and lab automation. So we’ll be very bio-, aero-, electronics-focused for the manufacturing side.”

He says San Diego also has the largest healthcare system in California, citing the VA San Diego Healthcare System, UC San Diego Health, and Scripps Health.

“For healthcare, one of our milestones is to provide robotic systems that would allow people to stay another 5 years in their homes (aging in place) rather than having to go to a managed care facility. In the U.S., we’re going to see a 70 percent increase in people above 65 within the next 5 years. A lot of them will have challenges in terms of getting out of bed, getting dressed, taking a shower, getting mobility to go to social functions, remembering to take their medications, and preparing meals. We have a big effort working with a major industrial sponsor on what it would take to build robots that would assist people in their homes.”

Christensen is working to bridge the university’s engineering, computer science, and social sciences teams.

“UC San Diego has the best cognitive science department in the world. We want to understand how robots can become the best possible complement to humans for work, for independent living. Given that we have a strong engineering department and a strong cogsci, if I put them in the same room, we can do things that you couldn’t do otherwise.”

In intelligent autonomous systems, Christensen is looking at air, land and sea autonomous vehicles.

“We have Qualcomm and NXP doing self-driving cars. We have SPAWAR,” referring to Space and Naval Warfare Systems Center Pacific, the U.S. Navy’s technical center in San Diego, which is working on next-generation unmanned systems and autonomous vehicles.

“We have a company called Litx that does self-driving trucks, and QualComm is trying to get into unmanned aerial vehicles big time,” he adds.

Look, ma! No Hands!

With his eyes and ears on every facet of the industry, Christensen is the closest we have to an oracle on robotics. But even he didn’t see this coming.

“The Roadmap is somewhat of a prediction of where we think the world will be 5, 10 and 15 years from now. But we clearly underestimated how fast autonomous driving cars were going to progress. We thought it would be 10 years out.” (The previous edition was published in 2013.)

“The fact that Audi, Ford, GM, Mercedes, and KIA all predict that by 2020 they will have autonomous driving cars for sale is pretty amazing. It’s also amazing how some of the technology is already getting into trucks.”

A platoon of self-driving trucks hit Europe’s roadways in 2016. Now autonomous semis are undergoing tests on U.S. highways and projected to go mainstream sooner than expected.

“That was a big surprise to us,” says Christensen. “We never thought it would go this quickly.”

He’s not entirely convinced that we’ll see driverless transportation in large scale by 2020, as many automakers have predicted. The driverless landscape is fraught with safety and liability implications, not to mention infrastructure issues (ahem, potholes!). In December, Michigan became the first state to adopt statewide autonomous vehicle regulations.

“We’ll start to see trucks that will be mainly driverless, or where the drivers on interstates are largely supervisors and driving is automatic,” says Christensen. “This is what the national highway association (NHTSA) terms Level 4 autonomy. Level 5 is a car with no steering wheel. That is clearly much further away.”

Collaborative Robots

Collaborative robots is another area progressing much faster than expected. An ABI Research study projected that the collaborative robots market will exceed $1 billion by 2020. Cobot manufacturer Universal Robots reported 2015 revenue of $61.44 million, a 91% increase over 2014.

“Today, all of the big robotics providers have collaborative robots,” says Christensen. “It’s by far the fastest growing market. We had not predicted that 5 years ago.”

Collaborative robots, the latest in machine vision, end effectors, and robots for welding, machine tending, assembly, packaging and palletizing … All the latest robotics technologies and tried-and-true automation will be on display this April.

Automate Preview

The place to see and be seen in the world of automation is at Automate 2017. The show has been dubbed “CES for smart people.” We’ll preview some of the technologies on display in February’s edition.

Also on tap for February, the Association for Advancing Automation will launch A3 Mexico to support and promote the rapidly growing Mexican automation industry.

Education in Robotics

In March, we’ll take a closer look at robotics education and the future of the job market. Christensen is leading the effort to create both undergrad and graduate programs in robotics at UC San Diego. But he also wants to focus on building a broader ecosystem that helps address the widening skills gap.

He says one of the challenges we face as a robotics industry is the historical focus on a four-year college education. We need more workers with a two-year trade education.

“We need more people on the factory floor that can operate and install our robots,” says Christensen. “For that reason, we are working with several of the local trade schools to build programs focused on the practical work. I can do all of these fancy things with robots, but if we don’t have the people to operate these systems, it’s a waste of time.”

Last fall, we profiled a few initiatives that aren’t wasting any time preparing the next generation.

K-to-Gray Lifelong Learning

STEM initiatives are helping plant the seed among K-12 students for a future in robotics, automation, and manufacturing. But experts note that this alone won’t be enough to bridge the widening skills gap. New emphasis is on “K-to-gray” lifelong learning.

“Traditionally we’ve educated people through the educational systems and then put them in the workplace, assuming their skillset would last a lifetime. We can’t do this anymore,” says Christensen. “Technology and the world is evolving too rapidly. We need to get into a mode where people learn for life.”

He says the impetus is on us to have the mindset to update ourselves annually. Employers also have a responsibility.

“How do we make sure that we don’t get to a society where we have A and B citizens, those that know the technology and those that have been overwhelmed by the technology? Employers will need to set aside 10 percent of the active work time for upgrading the skillsets of their workers.”

This Chicago-area manufacturer is answering the call by doing its part to close the gap. We’ll explore how other manufacturers are doing their part, and what skillsets will be in demand in a world with robotics consumerization.

Major Robot Makers – Yesterday, Today and Tomorrow

In April, we will profile the major robot manufacturers. You might be surprised by where they’ve come from and where they’re going. As we said last May, the automation biz is fast and furious.

All of the robot manufacturers are looking to the future and that means claiming their stake in Industry 4.0. In May, we’ll explore how cyber-physical systems, the Industrial Internet of Things (IIoT), and cloud robotics are building our smart factories.

Advanced Robotic Welding

Come June, we’ll focus our sights on advanced robotic welding, including friction stir welding, laser welding, and emerging technologies. We’ll explore how enabling technologies such as automatic seam tracking, coordinated motion, and vision and touch sensors are bringing unprecedented intelligence and autonomy to robotic welding.

Entertainment Robots

According to the International Federation of Robotics (IFR), from 2014 to 2015, unit sales of entertainment robots jumped by 29 percent to around 1.7 million units. Toys and hobby systems are popular with consumers. But this sector also includes industrial robots used in movie making (think blockbusters like Gravity), broadcasting, and entertainment installations that you might see at amusement parks and sporting events, even robot bartenders aboard cruise ships.

IFR projections have the entire segment at 11 million units by 2019, or $9 billion. Watch these entertainment-making robots in action and stay tuned for more robotic showstoppers in our July feature article.

Mobile Robots and Safety

Last year’s article on Mobile Robots and Intralogistics the Always-On Supply Chain garnered a lot of attention. This August, we’ll address the safety implications of this technology.

Mobile robots like the Omron Mobile Robot LD (pictured) are free roaming systems with sensors and other enabling technologies that help with navigation, as well as protect human coworkers and equipment from unintended contact. Watch this autonomous carrier robot in action.

Work is underway on a safety standard for this mobile breed of robots. The committee for R15.08 Industrial Mobile Robot Safety met for the first time last summer. They have their third meeting planned for February 28-March 1 in Dayton, Ohio, during the R15 Week of robot standards meetings.

Committee members represent key industry standards organizations, many traditional and mobile robot manufacturers, robot integrators, safety systems suppliers and integrators, robotic accessories suppliers, and major end users in the automotive and logistics industries.

Carole Franklin, RIA’s Director of Standards Development, says their main challenge is that the team is made up of experts in two different bodies of knowledge, robot safety and AGV safety.

“The members are busy familiarizing themselves with the other body of knowledge, so they can have informed discussions,” says Franklin. “We had two extremely productive meetings, where the big takeaway was a great deal of respect for each other’s expertise.”

At the committee’s next meeting in February, they hope to come away with an agreed-upon outline, for which they can then begin drafting content. Currently the scope of the committee includes two main areas: 1) mobile platforms with a sufficient degree of autonomy, and 2) mobile platforms with a mounted robot arm or manipulator.

Franklin says the standard will most likely be completed late 2018 and published during the first half of 2019. Meanwhile, mobile robots will keep rolling ahead, destined for a factory floor, warehouse, or retail store near you. Don’t be surprised if you’re soon sharing the sidewalk with a food delivery bot.

Industrial, Professional and Personal Service Robots – Safety for All

Before we move on, Christensen has a precautionary note on safety. We asked him if an accident on the consumer side could hurt the overall image and adoption of robotics.

“I think it’s a serious concern for the industry. In industrial robotics, safety has always been criteria number one. We have very strong safety requirements. But we need to make sure that our safety and standardization processes are much more agile than they are today.

“We need to make sure that safety is the primary objective for all these systems,” adds Christensen. “Otherwise it could seriously backfire for the entire industry.”

Robotics in Aerospace, Additive Manufacturing

We’ll revisit the aerospace industry in September. In contrast to last year’s popular article on robotics for airframe assembly and maintenance, this time we’ll focus on the aircraft component side of the business.

This will transition smoothly to October’s article on additive manufacturing, as many use cases are emerging in the aerospace industry. Robots are used for 3D printing aerospace components, automotive parts, casting molds, sculptures, and even a full-scale steel bridge across a canal in Amsterdam. Watch how MX3D defies gravity with six-axis 3D printing robots.

Autodesk shows us the “future of making things” with robots. We, too, can’t imagine doing our jobs and achieving our goals without them.

Rehabilitation Robotics

Always popular, our annual healthcare article in November will feature rehabilitation robotics. Robots in this space come in myriad forms, from exoskeletons and stair-climbing wheelchairs, to bionic limbs. Never mind the perfunctory references to Iron Man. Here’s a real-life superhero with a bionic grip and a big boy smile.

A strong will and hard work can get patients with paraplegia on their feet again. They just need some help from robotic therapy. Made by Swiss company Hocoma, the Lokomat® robotic gait therapy (pictured) reportedly improves patient outcomes by increasing therapy volume and intensity.

RIA member maxon precision motors makes the drives and controllers in the Lokomat robot. Only 40 millimeters in diameter, each of the maxon RE 40 motors in the robot’s knees provide 150 watts of power. Watch the Lokomat and other rehabilitation robots on duty at MossRehab, a top-ranked rehabilitation hospital in Pennsylvania.

“Boring” Robots

From rehab to 3D printing, to robots behind the scenes in Hollywood, all of these bots stimulate and inspire our imaginations. But many more robotic applications aren’t so sexy, at least not on the surface. “Boring” robots might lack the sparks and glamor of their welding brethren, but they are no less important to the industrial landscape.

Machine tending, sorting, packaging, non-destructive testing and inspection … sometimes it’s like watching paint dry. These are the mind-numbing jobs that would drive humans crazy if they had to do the same thing over and over again, day in and day out. Humans can’t begin to approach the precision, speed, and consistency of these tedium-tackling robots. We’ll show how “boring” robots aren’t so boring at all. They are essential.

Without these technological advancements, we become stagnant. Our evolution as human beings has always hinged on our ability to adapt, dream, and create. Robots that augment our capabilities and talents are here to help us dream bigger.