Twitter Timeline

FourByThree proposes the development of a new generation of modular industrial robotic solutions that are suitable for efficient task execution in collaboration with humans in a safe way and are easy to use and program by the factory workers.

The project was active for three years, December 2014-2017.

−Last week, December 15 and 16, FourByThree’s project consortium gathered for a plenary meeting that was celebrated at CNR-ITIA’s heaquarters in Milan, Italy.

The agenda focused on the main advances that have been carried out in the last few months in each of the project fields: modular design, actuators, programming framework, safety aspects, interaction, control and non-technical issues like the status of the four pilot scenarios, dissemination, exploitation and administration.

The session also included a visit to CNR-ITIA’s facilities, where some demonstrations on human-robot collaboration were shown and partners had the chance to examine one of the FourByThree prototypes allocated to this research centre. There was also plenty of time for bilateral meetings on some key technical aspects.

All partners agreed that the project is progressing correctly but the last 12 months will be crucial in order to develop, deliver and disseminate results. The consortium is motivated to give its best during the final year of the project.

All partners agreed that the project is progressing correctly but the last 12 months will be crucial in order to develop, deliver and disseminate results. The consortium is motivated to give its best during the final year of the project.

You can check our Twitter feed for more information on the meeting: @fourbythree_PRJ

Emerging technology in human robot collaboration (HRC) has transported dreams into reality, particularly in the arena of smart lightweight robots that are transforming the lives of individuals with mobility issues, and improving the quality of daily work in many application scenario. Direct, physical interaction between a human and a robot has potential to provide assistance (as well as rehabilitation) which can extend the human user’s physical capabilities.

FourByThree represents a major step forward the possibility to tailor the robot on the real needs of the persons, creating modular devices that augment their capacity.

However, the adoption of lightweight robots opens important Ethics problems related to how to guarantee the human safety: to be successful, the robot must be able to realize the system-level objectives without compromising the subject’s safety in every possible usage condition.

The FourByThree aims at scattering the common approaches by widely adopting serial-elastic-actuators for moving and controlling the robot chain. Indeed, when it comes to the mechanical interface between motors and loads, “the stiffer the better” is a traditional premise of good design, but it is far to be optimal particularly for cooperative robots, because elasticity can be used for a wide variety of purposes, and especially for safety.

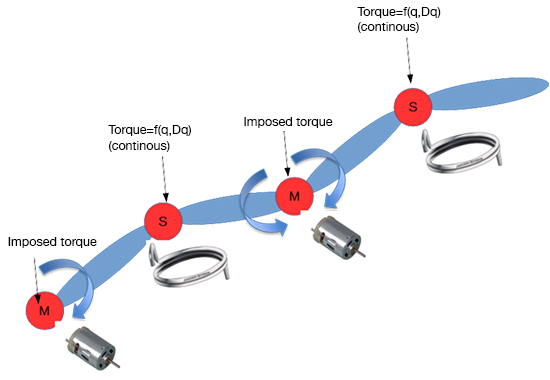

Figure 1: Control of a Kinematic chain through series elastic actuators

Figure 1: Control of a Kinematic chain through series elastic actuators One effect of the series elasticity is to low-pass filter shock loads, thereby greatly reducing peak gear forces. The proper amount of interface elasticity can substantially increases shock tolerance while maintaining adequate small motion bandwidth.

Although compliance can help improve safety, it must coexist with other system objectives. In many cases, the system is to track a desired trajectory, e.g. to assist in a defined task. The more complex dynamics of compliant actuators requires proper model selection and controller design to give satisfactory performance. However, in traditional motion control, compliance is usually minimized in both the drivetrain and controller design to reduce mechanical resonance and improve rejection of load-side disturbances.

To consider the effects of the elastic element, a model for the series elastic actuator with load-side dynamics has to be introduced, validated, and then used for controller design.

The performance and safety of several control architectures are therefore the core of the control activities in FourByThree project.

Implicit in the design of the controllers is the avoidance of “high-gain feedback control”. Although disturbance observers and other advanced loop-shaping techniques may be able to provide improved performance, any sort of high-gain feedback can be dangerous in the event of a hardware malfunction or other system error. Another consideration for real-world implementation of any compliant actuator is unmodelled dynamics or disturbances. For unmodelled dynamics on the subject side, these forces will affect the system the same as the subject interactive torques. Without any distinguishing characteristics (e.g. different frequency bands), it is difficult to separate these disturbances from the subject’s input. Especially in low-stiffness implementations, this may compromise the system performance, so careful modelling and feedforward compensation is critical.

FourByThree, therefore, aims at tackling the problem through two concurrent actions: to develop innovative motion planner, that minimizes the dynamics disturbances for the control; to develop advanced control strategies – based on the inversion of the system dynamics – to grant large controllable bandwidth.

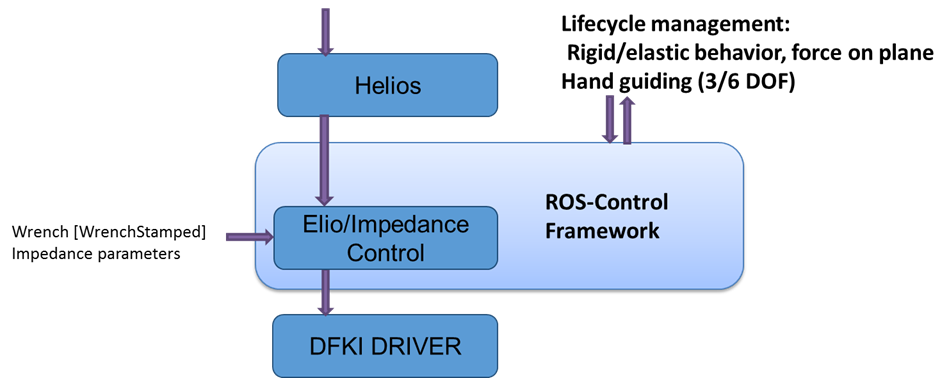

Such modules are named HELIOS – the smooth motion interpolator – and ELIO – the advanced coupled centralized axes controller. HELIOS and ELIO have been designed in order to increase dramatically the potential field of application of the FourByThree robot: the robot will be able to track trajectories in the Cartesian space accurately, and to react fast and robustly to external forces, allowing high-quality force control tracking.

Around this powerful engine, different high-level controllers can be therefore applied to improve the human capabilities while executing cooperative industrial tasks: vision servoing modules as well as hand-guiding modules can be just plugged as additional functionalities.

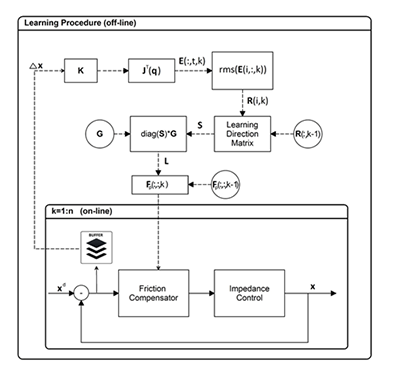

Figure 3: Advanced Learning and Adaptive Strategies for High-level Interaction modalities

Figure 3: Advanced Learning and Adaptive Strategies for High-level Interaction modalitiesFurther, FourByThree robot will be provided by innovative algorithms also for the hand-guiding. Indeed, a standard manual guidance with gravity and friction compensation does not directly allow the compensation of an unknown manipulated component weight (i.e., requiring an external observer to estimate the inertial properties of the manipulated part).

The FourByThree robot will be provided by adaptive impedance controllers based that autonomously will continuously update the real-time the set point of the impedance control based on the user-applied forces at the user-interface (e.g., an handle at the robot end-effector). The proposed control law allows to perform fine positioning of the robot by applying small forces, while allows a fast/large motion positioning of the robot by applying higher forces. Moreover, based on the derivative of the user-applied forces and of the measured Cartesian velocities, a switching logic has been implemented in order to enable/disable the empowering adaptive manual guidance control strategy, allowing compensating for the manipulated component weight during both the motions and the steady states.

FourByThree robot, therefore, will be not only a modular robot in term of HW solutions, but the control architecture itself will be the core that make the robot modular in term of the potential expandability of its functionalities to many different application requirements. FourByThree robot will make affordable the assembly of unique products or products with a small-scale lot size and large-scale lot size with a high diversity of variants, many manufacturing steps that are nowadays difficult or non-economic to automate. The robot will be a real assistance system, and the hybridization of biological and technical systems, a so-called “Human Hybrid Robot” (HHR) will be enabled by the high-performance in position and force tracking of the FourByThree robot.

Through several decades of research new opportunities have emerged in automation engineering. These opportunities have led to new robotic and assistive systems that are used to arrange a clear and concise workflow for employees. These systems are used to provide important information to the operator or to aid them in the tasks of acting, sensing, and deciding. Concomitant with current market conditions, the degree of automation has been increasing. However, experience has shown that full automation of production cycles is often inefficient [1]. High numbers of product varieties combined with small batch quantities hold a challenge for the future of automation [2]. To achieve this efficiency, it is necessary to develop flexible and adaptable production systems that can be applied to a variety of tasks [3].

Under the FourByThree research project, research assistants from ZeMA will work on developing solutions suitable for the flexible automation of chosen production processes by means of Human-Robot-Collaboration (HRC). A vital element of the FourByThree project is the development of a unique robotic system that allows for automation to be easy, flexible, and cost-efficient. The most significant advantages of the FourByThree robotic system are safe and collaborative operations, fast initial startup, intuitive controls, and residential mobility. As a result of these features, the FourByThree system allows for human and robotic cooperation in a whole new way. This is achieved through combining the cognitive and locomotive abilities of humans with the pinpoint accuracy and endurance of highly technological robots [4]. To realize this collaboration, the development and implementation of a new robotic design is necessary.

The goal in FourByThree is to develop a new generation of robot systems which is modular, flexible and safe for HRC. Therefore the work package ‘Robot Design’ comprises the subtasks of safety, actuators, control system, interfaces, joining elements, and software (Shown in figure 1). Safety is declared as a general topic because of its importance within HRC. It also, however, influences safe construction of the actuators as well as an HRC design of the interfaces and joining elements. Examples of these include reduced width gaps or curved edges. Next to the modular design of the hardware components, the control system and software will also be desiged to be modular in their components and communication. In brief, using the components developed within the FourByThree project, operators will be able to set up an HRC robotic system that provides for the needs of the application within a short period of time.

The FourByThree robotic system is designed for and influenced by HRC. Unlike traditional industrial robotic systems, the modular robot can be optimally adapted and used for different tasks and applications. The development of designs for the FourByThree robot system is based on target production and also scenario analysis in four pilot studies. These pilot studies involve different industrial sectors which are classified into tasks including welding, riveting, handling, and bolt fitting. The design uses a modular construction kit which is developed according to norms and directives for collaborative robotic systems. This kit consists of major robotic elements such as the ‘base’, ‘joints’, ‘link elements’, and ‘flange module’ (Shown in figure 2). Therefore, depending on the applications, different kinds of robotic systems can be configured using these elements. The setup of the robotic system is based on virtual modeling of kinematics derived from a work space analysis. Using simple calculations, it is possible to determine the custom configuration of the robot system based on the construction kit. Once the application and configuration are known, assembly of the robot with simple joining steps is possible. Directly after assembly, the robot is ready for use. In brief, FourByThree’s robot design allows operators a custom robotic system suitable for a wide range of applications while also allowing for Human-Robot-Collaboration.

Within the three years of the FourByThree program, seven robotic arms are scheduled to be tested. Out of these seven robots, three are intended for research and development while four will be put to use according to specific work scenarios. The specifications of these prototypes result from the drives used, which have already been developed by the project partner DFKI. Different robotic structures have been implemented for each of the three existing prototypes (Shown in figure 3). Besides reach and payload distinctions, they also have different degrees of freedom. This displays the system’s modularity as well as its broad range of applications.

As described before, this modular and easy to use robot construction kit is designed with HRC in mind. The figure represents the three robot prototypes which were set up in under six months using the FourByThree construction kit. In order to ensure the quality of the modules and accelerate set-up times, different kinds of material were used. Some of these materials include aluminum, CFRP and 3D printings. Other improvements include taking care of safety concerns in the design were to decrease the injury potential by reducing width gaps, implementing covers, and installing security screws next to the safe actuators.

In conclusion, the development and combination of FourByThree’s construction kit for safe HRC allows the operator to quickly and efficiently set up a robotic system on the shopfloor. Based on each projects’ requirements – modularity, safety, ease of use, and efficiency – a new robotic system can be defined. As a result, the operator is able to set up a safe robotic system for Human-Robot-Collaboration which suits their needs in no time at all. Furthermore, the ability to easily reconfigure allows the system to be continually used in different applications. Changing the system specification through adding and removing degrees of freedom or varying the reach of the robot with different link modules gives it this advantage. Due to the system’s reusability, it is not only easy to reconfigure and maintain, but also cost effective.

[1] Müller, R.; et al.: Wandlungsfähiges Montagesystem für Großbauteile am Beispiel der Flugzeugstrukturmontage. In: Zukunftsfähige Montagesysteme. Wirtschaftlich, wandlungsfähig und rekonfigurierbar. Stuttgart: Fraunhofer Verlag 2013.

[2] McKinsey&Company (Hrsg.): Zukunftsperspektive deutscher Maschinenbau. Erfolgreich in einem dynamischen Umfeld agieren. Berlin, 2014.

[3] Corves, Burkhard; Müller, Rainer; Huesing, Mathias; Janßen, Markus; Riedel, Martin; Vette, Matthias (2010): Reconfigurable assembly systems for handling large components.

[4] Müller, Rainer; Vette, Matthias; Geenen, Aaron (2015): Potentials of Human-Robot-Cooperation in Aircraft Assembly Systems. In: SAE International Paper 2015, 15.09.2015. Online http://papers.sae.org/2015-01-2507/

Source: Robotiq

Now that we’ve had time to reflect on Automate 2017, here are our 5 most significant takeaways from last week’s event.

The vast majority of robot manufacturers are providing cloud-based services these days, from simple data backup to cloud-based data analysis.

Probably the most dynamic example of this trend in action is the ‘in.control’ system developed by Tend robotics, which allows you to monitor, control, and train robots remotely via a cloud-based app on your smartphone or tablet device.

Source: Plastics Today

By 2025, the market for collaborative robotics is expected to reach $12 billion

The automation sector had another exceptional year; it’s best ever, in fact. In 2016, the North American robotics market broke all time records for orders and shipments, according to statistics from the Robotic Industries Association (RIA; Ann Arbor, MI). A little more than 34,600 robots valued at approximately $1.9 billion were ordered in North America, representing growth of 10% in units over 2015, according to the RIA. Many of those robots were recruited by automotive OEMs, with shipments into the automotive market growing 25% relative to 2015. In the food and consumer goods industries, orders increased by 32% last year, adds the RIA.

Collaborative robots, or cobots, probably did not account for a large piece of that pie—Barclays Equity Research estimates that cobots racked up $120 million in sales in 2015—but their market share is expected to soar in the coming years. Part of the reason is cost, which is expected to decline 3 to 5% annually through 2025, according to Barclays. By that year, the collaborative robotics market is expected to hit $12 billion.

As more and more employees begin to rub shoulders with cobots in the workplace, we thought it might be a good time to speak with someone who knows a thing or two about the technology: Roberta Nelson Shea, Global Technical Compliance Officer at Universal Robots USA Inc. (Ann Arbor, MI). She shared some insights with PlasticsToday on things to consider when planning to purchase a cobot as well as safety issues to keep in mind when deploying them. She will be addressing the latter topic at a session during the Smart Manufacturing conference track at PLASTEC West next week in Anaheim, CA.

Shea sometimes sees two approaches to investing in collaborative robotics, neither of which is ideal. “Some get a cobot without giving any thought about how it’s going to be used ahead of time,” says Shea. And that could be OK, she adds, unless the end effector is a cutting tool, for example, in which case you really have to think about safety issues. “Or they overthink it and become paralyzed by the notion of all the things a cobot can do and don’t know how to move ahead. The best approach is somewhere between these two paths.”

The primary factor to consider when implementing collaborative robotics on your factory floor, says Shea, is to deploy the robot in such a way that it will not hurt someone. Power- and force-limiting features can be built into the robot to ensure protection of human co-workers without relying on the guards and cages of conventional automation systems. Beyond that, you want to limit the areas where clamping occurs, as in pick-and-place applications, and give the robot system (the robot plus the end-effector and part) sufficient space to perform its task.

“Material handling is a typical application, so you design the workspace such that clamping will not occur anywhere but at that specific place,” says Shea. “The only thing you need to worry about is where the end effector interfaces with the part during material-handling operations. And you don’t want to position the robot up against a wall, for example, where a person standing between the robotic arm and the wall could be pushed upon,” Shea adds.

You can use a pendant to program our cobots, says Shea, but most people do it by guiding the robotic arm and mimicking the motion they would make to perform a specific task. That builds in safety in and of itself, she adds. “When you think about how you go about picking up something and moving it from one surface to another, you make a gross movement and then gently put your hand down. If the robot is programmed to make these human-like motions, that lessens the likelihood of the cobot making a hard or abrupt motion that could be startling to a person.”

Plastics processors are finding multiple applications for cobots, some of which are unexpected, says Shea. “Pick and place is the most common task, and some manufacturers have adapted that to testing operations. One application I have seen is the part being removed from a tool and put into a testing fixture. The arm manipulates the part for proper orientation for inspection.

“Another application that I would not have thought of is removing flash, which can be sharp, from a molded part,” says Shea. “The end effector picks up the part and moves it to a grinder or buffing wheel and holds it at a particular resistance.” In this instance, she adds, safety comes from a cobot performing a task that could cause injury to a human worker.

Shea will address multiple safety issues involving collaborative robotics at the PLASTEC West trade show and conference in Anaheim, CA, next week. Part of the Smart Manufacturing conference track, her presentation, “Safety First: Working on a Team with ‘Fenceless’ Robots,” is scheduled for 9 AM on Feb. 7. The show runs from Feb. 7 to 9 at the Anaheim Convention Center.

Also of note: Three collaborative robots from Universal Robots will greet show attendees at the expo entrance. Moving through pre-programmed cycles, the cobot arms equipped with monitors will feature videos of a variety of industrial tasks now handled by Universal Robots, from CNC machine tending to polishing, wire cutting, injection molding and pick & place applications. As in many of their real life installations, the cobots will be placed in a high-traffic area where they will operate with no safety guarding alongside people.