Industrial robots have changed many of their characteristics during these last years, enabling the evolution of the automation technology, from the typical robotic applications where the robot is fully surrounded by a peripheral fence system, to the most advanced “cobots” available in the market. Today we can find robots working hand in hand with the operator to carry out manual tasks. In order to achieve such direct cooperation between human …Read More

Robots and humans can work together with new ISO guidance

Source: ISO Organization Human and robot system interaction in industrial settings is now possible thanks to ISO/TS 15066, a new ISO technical specification for collaborative robot system safety. Collaborative robotics is when automatically operated robot systems share the same workspace with humans. It therefore refers to a system or application rather than a particular type or brand of robot. Industrial robots do not include an “end effector”, that is, the device …Read More

Collaborative Robots Working in Manufacturing

Source: Manufacturing Tomorrow Because cobots are affordable, highly adaptable, and almost plug-and-play, small and medium-sized manufacturers are eager to take on this technology, and some analysts expect that this segment of robotics will see substantial growth. The Boston Consulting Group predicts that investment in industrial robots will grow 10% each year for the next ten years in the world’s 25 biggest export nations, when the robots will take over 23% …Read More

User-defined gestures for controlling primitive motions of an end effector

Complete article Abstract: In designing and developing a gesture recognition system, it is crucial to know the characteristics of a gesture selected to control, for example, an end effector of a robot arm. We conducted an experiment to collect a set of user-defined gestures and investigate characteristics of the gestures for controlling primitive motions of an end effector in human–robot collaboration. We recorded 152 gestures from 19 volunteers by presenting …Read More

Why the new ISO/TS 15066 is important for the robotics industry

Source: Robotiq Collaborative robots are relatively new and standards are usually long to write down, so it only make sense to have the new ISO/TS 15066 regulation freshly printed out in the last couple of weeks. As we are working with collaborative robots and are a part of the world of robotics, it makes sense to understand the importance of such a regulation and potential future standard. The regulation hopes to …Read More

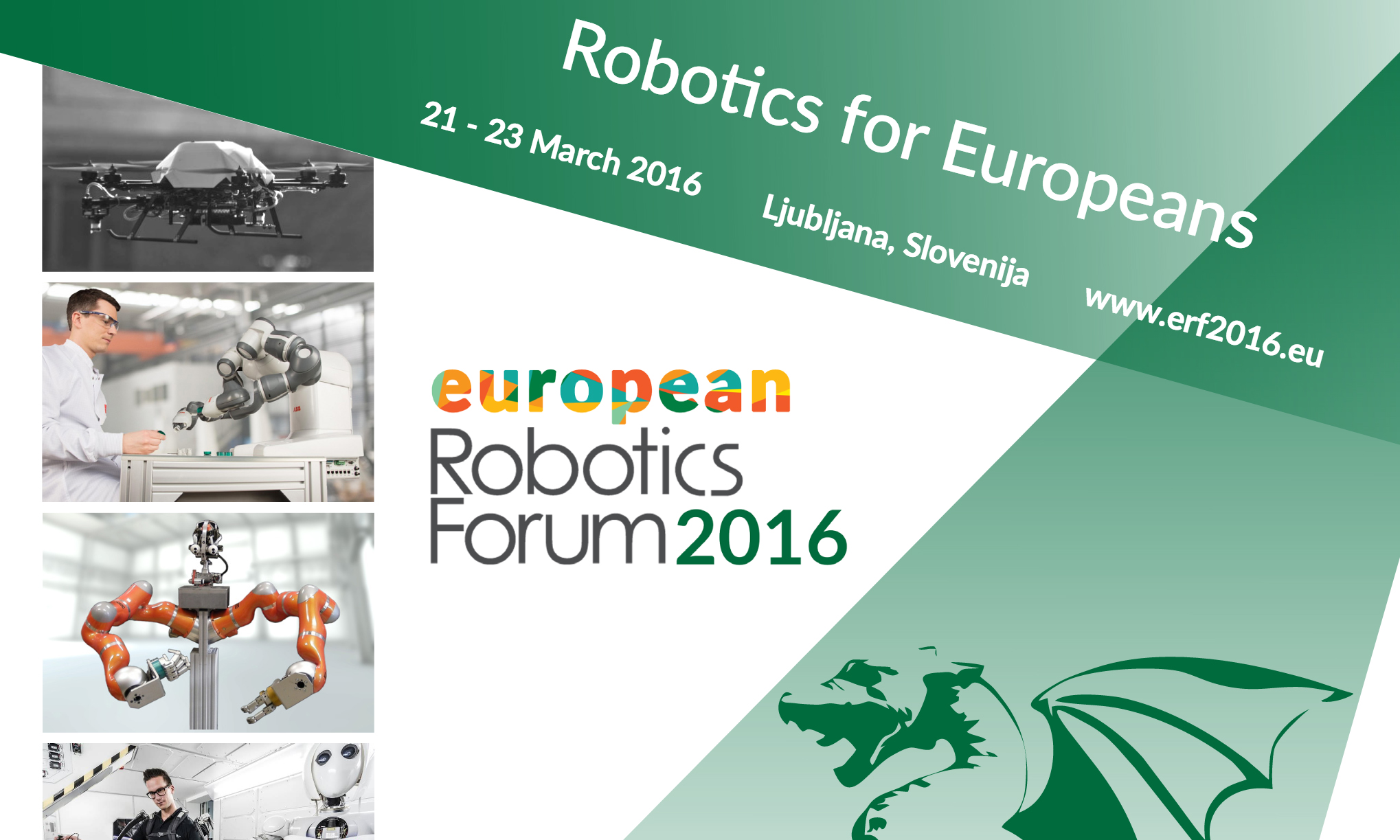

FourByThree in the European Robotics Forum (ERF 2016)

This year FourByThree will also attend the European Robotics Forum, which will take place in Ljubljana, Slovenia, on 21-23 March 2016. FourByThree will be present in the seventh edition of the congress within the context of the 3rd Workshop on Hybrid Production Systems. This workshop is dedicated to research projects which focus on Human-Robot collaboration. The workshop’s ultimate goal is to continue the dialogue among the projects themselves, as well …Read More

5 Robotic Essentials for SME manufacturers

Source: Hannover Messe For small to mid-sized manufacturers, any gain in productivity can have a huge impact. Automation offers significant advantages, but many small and mid-sized enterprises (SMEs) believe that robotics is out of their reach. These organizations can’t afford large, complex robots that don’t fit within their limited floor space, that require specialized personnel to program and maintain them, and that are simply too expensive, with a payback period …Read More